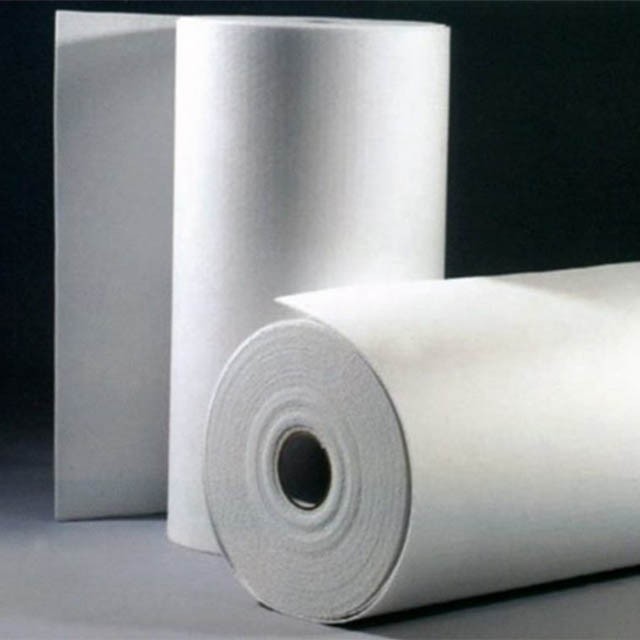

1.Easy to wrap, shape or cut

2. Lightweight

3.Low thermal conductivity: Low heat storage

4.Good uniformity and smooth appearance

5. Good flexibility and toughness and resistance

to avulsion

6. Good dielectric strength and sound insulation

7. Excellent thermal shock resistance

8. Excellent chemical satability and machining

Property

9. Excellent corrosion resistance

| Item | Standard | High Pure | High Aluminium | Zirconium | |

| Max. Temperature (°C) | 1050 | 1150 | 1260 | 1430 | |

| Shrinkage on Heating (%) | 800°C x 24h ≤ -3 | 1000°C x 24h ≤ -3 | 1280°C x 24h ≤ -3 | 1400°C x 24h ≤ -3 | |

| Organic Content (%) | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | |

| Thermal conductivity by mean temp. (W/m.k.) (250kg/m3) | 200°C | 0.055 ~ 0.065 | 0.060 ~ 0.070 | ||

| 400°C | 0.110 ~ 0.120 | 0.105 ~ 0.125 | |||

| 600°C | 0.160 ~ 0.170 | 0.170 ~ 0.180 | |||

| Chemical Composition(%) | Al2O3 | 43 | 47 | 55 | 38 |

| SiO3 | 53 | 51 | 44 | 44 | |

| Fe2O3 + Ti2O3 | ≤ 1.2 | ≤ 0.3 | ≤ 0.3 | ≤ 0.2 | |

| CaO + MgO | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | ≤ 0.2 | |

| NaO + KO2 | ≤ 0.5 | ≤ 0.3 | ≤ 0.3 | ≤ 0.2 | |

| Density (kg/m3) | 170-230 | ||||

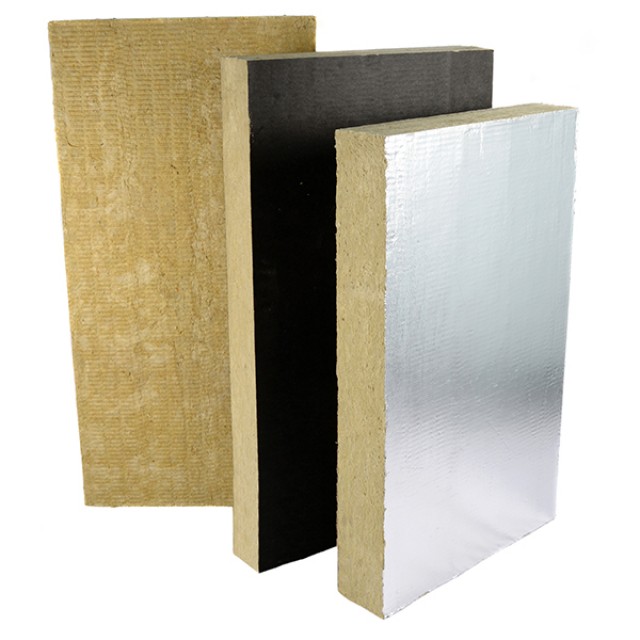

1.Die cut gaskets between castings in coke oven doors, blast furnace hot air piping, aluminium heat treating furnace, tuyeres and heat treat furnaces.

2.Backup for brick and monolithic refractories in blast furnace stoves, piping, tundish, ladle, hot metal cars, trough etc.

3. Mould wrapping for controlled cooling

4.SEN isulation wraping

5.Shield for welding & brazing operation

6. Rotary klin back-up insulation

7.Fabricated into tapout cones for Aluminium industry.

8. Strips in bottom of ingot mould for sealing

9.Expansion joint packing

10.Induction coil liner

11. Mould liner

12. Silencer interleaf

13.Ladle & tundish insulation

14.Asbestos paper replacement

15. Hot top linings

16.Thermal and electrical insulation